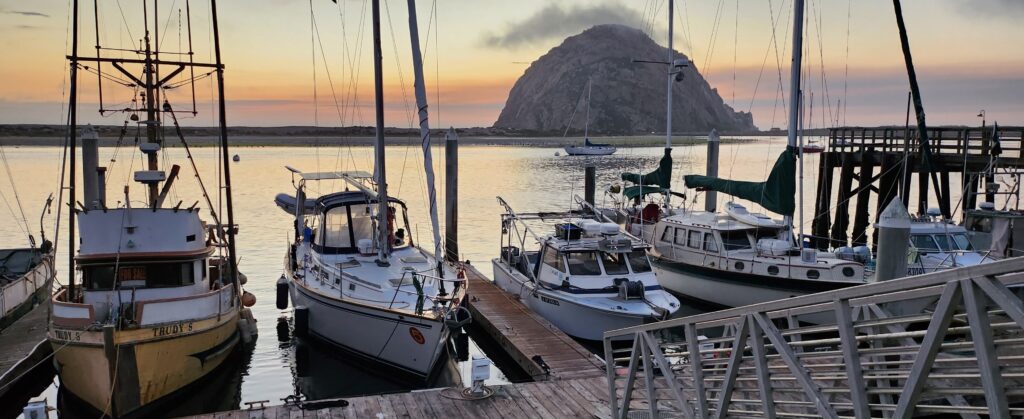

Before I dive into the project talk, I’d like to say that I ADORE MORRO BAY! To the point of it being on my list of places to return to in future landlife. My adoration is partly due to Morro Bay’s proximity to Paso Robles, Hope in Spades Ranch, and friends. Mostly, it’s just a great town. It’s small. Like the kind where you would eventually know almost everyone. It’s filled with character, sometimes making it feel old after decades in Vegas, yet also quaint. It’s close enough to SLO (San Luis Obispo) to get one to Costco and the “big stores.” Not so small as to not have any services or handy stores.

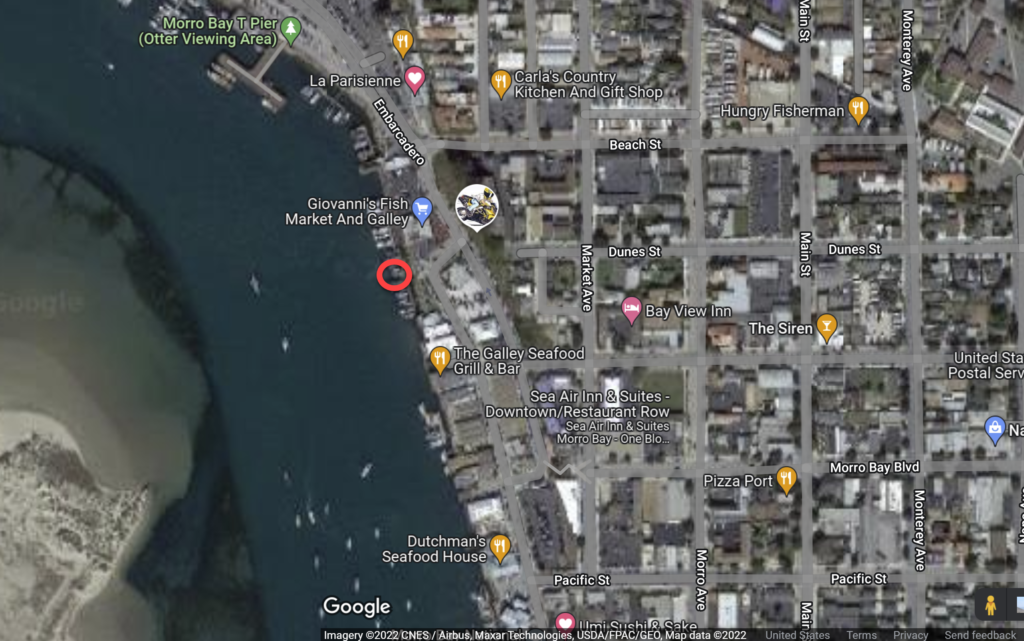

We arrived here in late September. Took a few days to decompress and catch up on sleep. For October and November, we’ve been in a slip in the heart of the embarcadero. Basically, at Anchor Memorial Park, between Giovanni’s Fish Market and House of JuJu.

It’s a short walk to pretty much everything. Even Albertson’s is only .6 miles up Harbor St. We are .1 mile away from what has become our go-to restaurant, Hofbrau Morro Bay–if you come here, do yourself a favor, get the French Dip and Clam Chowder. They also have tasty brewed iced tea.

Project 1: Refrigerator Swap for Tropics

MACH 5 came with a good-sized, top-opening fridge and a ridiculous shoe-box-sized “freezer.” I use quotes because it barely froze water to a solid enough state to be called ice. Barely. A pint of ice cream would turn into a Wendy’s Frosty, not even DQ Blizzard consistency.

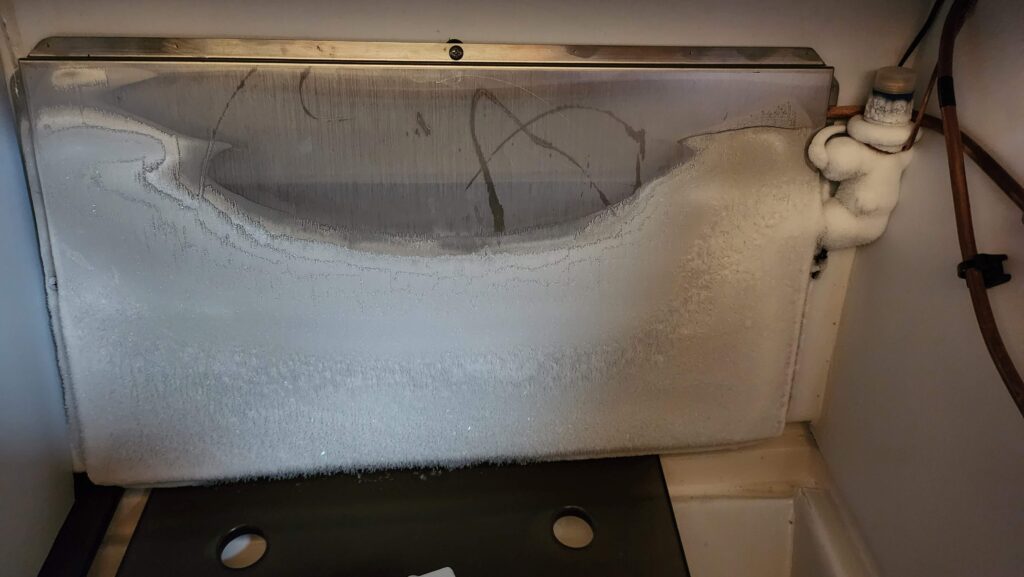

The Dometic/Adler-Barbour unit was not original but also was not new. It cooled itself via air. So whatever the air temp in the boat was dictated how efficient the fridge could be. Meaning, cold-ass summer in San Fran = happy fridge; 90+ temps during a Stockton summer = not even keeping cold foods at a safe temp. It has prevented us from cooking at home and being away from civilization. Going south would only make it worse. This is a great setup if you sail on weekends or for short stints.

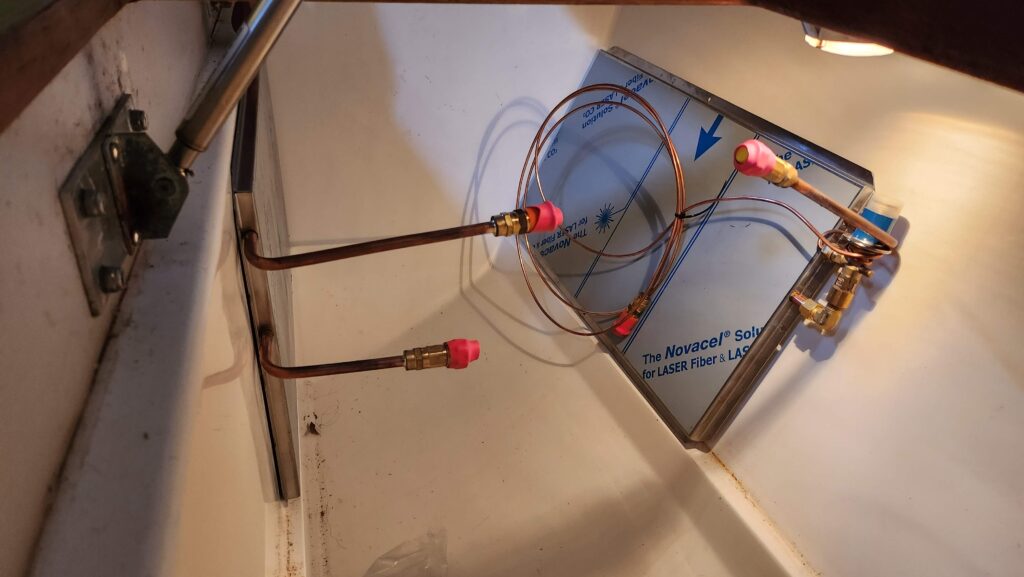

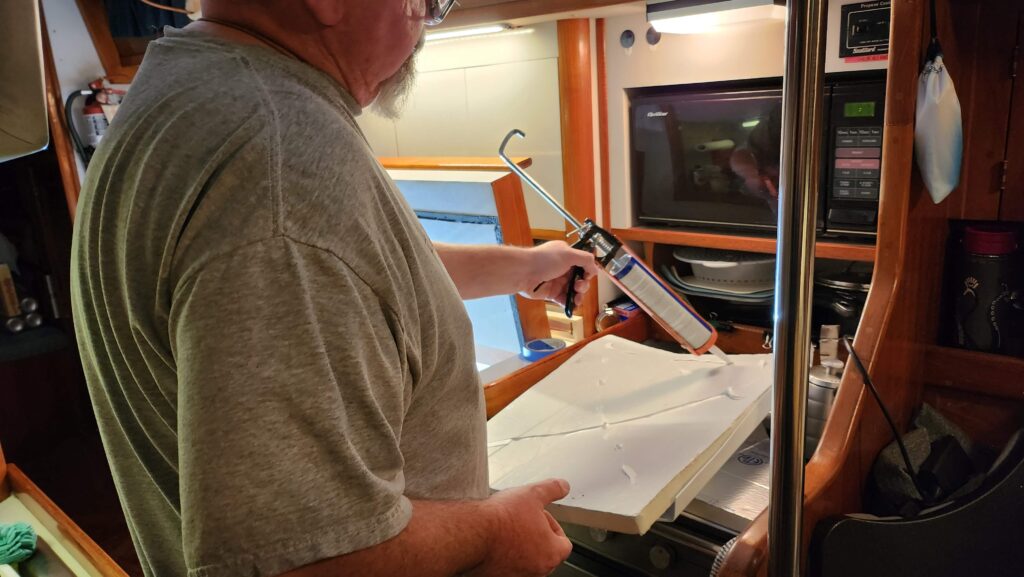

As liveaboards and cruisers, we needed better insulation, a bigger freezer, a freezer that freezes, and a water-cooled system. Our vendor-turned-friend, Alan from The Boat Guys in Alameda, recommended a SeaFrost system that is air-and-water cooled along with added insulation.

Mark spent hours on the phone and on video calls with Alan as Alan taught Mark how to do various parts of the installation that weren’t obvious. Mark has new tools and new skills!

Let’s take a pictorial journey of the process.

The fridge project took 5 full days of work. Not including research, prep, or maintenance that we need to do. It worked great while we still had electricity. That’s the project we are doing today and has been for days or weeks. So it feels.

More on the power upgrade, next blog post.