No matter what you buy used, at some point in your ownership, you have a moment of what was the prior owner (PO) thinking? With a boat, it seems to happen almost daily.

One of the reasons to haul out of the water was a leaky seacock. Ah, but we were wrong about the leaky bit. The PO strikes again!

A seacock is a valve on the hull of a boat or a ship, permitting water to flow into the vessel, such as for cooling an engine or for a salt water faucet; or out of the boat, such as for a sink drain or a toilet. Source: wikipedia

In the year that we’ve had Mach 5, the seacock for the heat pump (air-con/heater) has allowed in the teeniest dribble of water. The wood backing plate was rotted and delaminating. I thought I had a pic of the before state but apparently no. I’m guessing you can imagine plywood that’s wet and falling apart.

plate…so we thought.

Mark removed the old seacock and the backing plate the other day. He started sanding off the remnants of plywood and epoxy on the inside of the bilge, then moved to the outside for the same. To compare, if you are painting a surface, then you know you need to have any old glues, paint, tapes, and random organic bits removed before you paint. Same thing for installing a new seacock — but even more because if you leave the teeniest of gaps, water will flow in and eventually sink your boat.

Are you guessing what comes next???

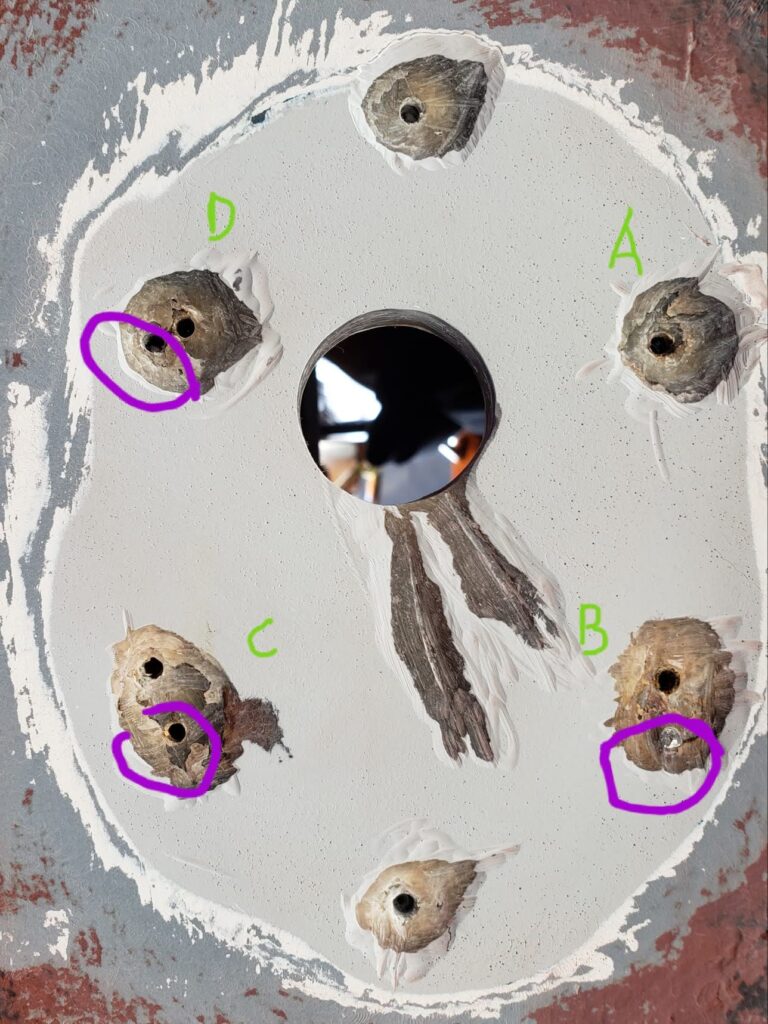

Enter this pic:

The thru-hole and seacock for the heat pump also have a strainer cover to prevent the intended water that runs the heat pump from sucking in sea life. No twigs or kelp or whatever sucked up into the system to clog it. GREAT solution!

What Mark discovers on the outside hull are in the purple circles in the above pic. Some PO moved the strainer cover and didn’t seal the old screw holes. Some of the old screw holes still have screw bits in them...btw, old screws do not create the water-tight seal you want for a boat.

The seacock wasn’t leaking. The strainer didn’t cover the old holes well. Allowing water to slowly seep into the plywood backing plate. Rot that plywood. Then at some point, the saturation became so much that a droplet or two of water a day came in the bilge (the name for the inside area around the thru-hull).

Now Mark gets to properly plug the holes, remove the screw bits, do some fiberglass repair, and install the new seacock and backing plate.

Ah, POs.