post began on 5 July 2021

As you may recall, we learned about the windlass–the mechanical device that pulls up, and sometimes lowers the anchor–in a hard lesson that involved stress and Towboat US on 1 June 2021. Within a week, Mark had performed a few diagnostics and decided the windlass burned out. Now came the task of removing the beast. Little did Mark know in early June what a beast it was.

The windlass/ˈwɪndləs/ is an apparatus for moving heavy weights. Typically, a windlass consists of a horizontal cylinder (barrel), which is rotated by the turn of a crank or belt. A winch is affixed to one or both ends, and a cable or rope is wound around the winch, pulling a weight attached to the opposite end. The oldest depiction of a windlass for raising water can be found in the Book of Agriculture published in 1313 by the Chinese official Wang Zhen of the Yuan Dynasty (fl. 1290–1333).[1] The Greek scientist Archimedes was the inventor of the windlass.[2]

https://en.wikipedia.org/wiki/Windlass

update 7 July 2021

After much research and a few consults, Mark ordered our new windlass! The lucky winner to join us on Mach 5 is Lewmar V4 Windlass (vertical with gypsy and drum). The old windlass was probably one size too small for the boat. This one is probably one size too big. It can pull up 2,750lbs with a 1600W motor that draws 125amps. The unit comes with a wired remote, and we are adding a wireless one as well. We also went with 300′ of 5/16″ Titan G4 chain. Naturally, we have a new anchor too–a 44lb Rocna with scoop and roll bar.

update 9 August 2021

We are back and the windlass has arrived! The fun begins.

update 16 August 2021

Successful few days! It took 2.5 days of running six much thicker electrical wires where there were two. It sometimes seemed hopeless, often seemed like the narrow channel from the point of the v-berth up to the deck was a one-way street of up only.

Today, Mark was able to finish wiring the electrical while John from the boatyard continued to work on the anchor locker refit (of course, it needed changes too) and cutting the holes in the deck for the new windlass. Since the new windlass can’t possibly use the same footprint that the old one did–even though same manufacturer–last week, Eduardo from the boatyard created a new “deck” surface from G10. Which is just barely visible at the bow where the blue tape is in pic below.

For about 5 days, we’ve lived with all of the v-berth contents in the salon. So believe it or not, I am typing this on the laptops shown in the pic. Do you see it?

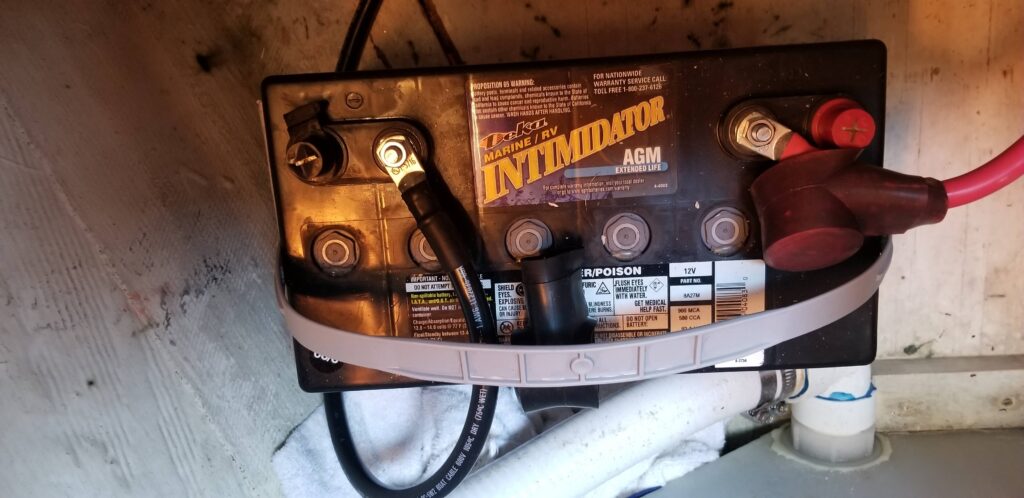

After loads of wiring, toning, and cussing, the windlass motor ran today! It has nothing to pull yet, but we have proof of life! That’s the end of today’s update. Here are some wiring and battery pics just for fun.

Mark had to replace a corner of the chain locker with the washdown faucet. It was his first boat fiberglass project!

update 20 August 2021

The windlass is fully installed and WORKS!!!!!

update 21 August 2021

Believe it or not, this little barrel contains 300ft of chain!

update 22 August 2021

The chain is laid out in 25ft pieces and ready to be marked with zip ties so we can tell if we are at 75ft or 150ft.

update 26 August 2021

The anchor locker rebuilt is done! The windlass works and has 300ft of new chain plus a new anchor on it!

We can go back to home’s home (Stockton) now!